EpiX - 10X SUPEROXALLOY ABRASIVES

SOLVES “PURSUIT OF EXCELLENCE” CHALLENGES

Choose EpiX superoxalloy abrasives for…

• Fabrication, device and equipment manufacturing

• Specialty parts and coatings

When surface quality matters:

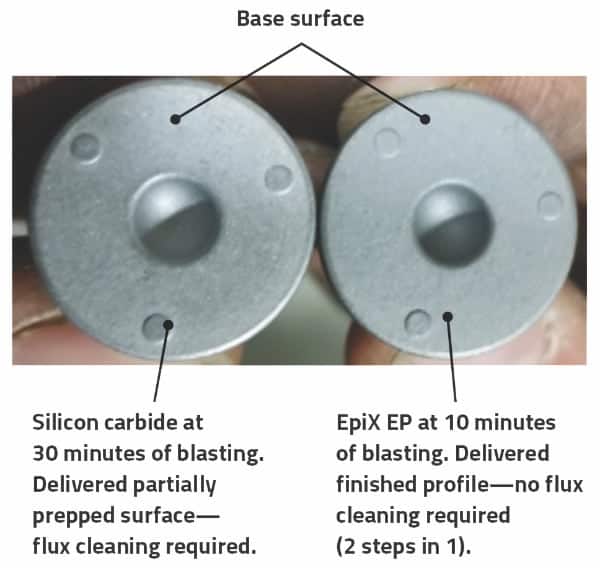

- Exacting surface quality, profile, appearance and uniformity

requirements

- Zero tolerance for iron contamination or embedment

- Ultra-low blasting abrasive dust

High-efficiency manufacturing and fabrication processes:

- Speed: reduce time required for surface preparation

- Produce clean, finished surface in one step, with no required

secondary finishing, cleaning or polishing

- Reduce blasting media consumption: contain and reuse abrasives

- Reduce/eliminate throughput disruption caused by rework

Efficient, precision coating removal:

- Remove thick, tough powder coatings, elastomerics, multi-layers, two-part epoxies—with no burn off or scraping

Strict environmental, health and safety blasting requirements:

- Clean blasting abrasives

- Ultra safe

- SSPC-AB 1 Class A (Less than 0.1% Free Silica)

- Extremely low dust

- Sustainable 100% recycled material

- Unparalleled environmental safety: air and water quality - Can be harmlessly left on the ground or in water (TCLP)

EpiX Grades

EpiX Packaging Options

EpiX superoxalloy abrasive on the job...

EpiX Ordering Information

| STOCK # | Profile | Packaging | Reusability @100PSI | Bulk Density |

|---|---|---|---|---|

| KX1052 | EpiX EP - Enhanced | 2,000 lb SuperSack | 4 - 8 times | 100-110 lb/ft3 |

| KX1054 | EpiX EP - Enhanced | 100 lb Bags | 4 - 8 times | 100-110 lb/ft3 |

| KX1058 | EpiX EP - Enhanced | 50 lb Bags | 4 - 8 times | 100-110 lb/ft3 |

| KX1062 | EpiX MP - Medium | 2,000 lb Bags | 6 - 12 times | 100-110 lb/ft3 |

| KX1064 | EpiX MP - Medium | 100 lb Bags | 6 - 12 times | 100-110 lb/ft3 |

| KX1068 | EpiX MP - Medium | 50 lb Bags | 6 - 12 times | 100-110 lb/ft3 |